Since May 2010 track-bound ballast wash with our new RM 95-800 W.

- Previously, a full excavation had to be carried out for the ballast cleaning of heavily soiled or contaminated tracks. The dirty old bedding was fed to a semi-mobile washing plant, broken, screened and washed. The cleaned gravel was then transported back to the construction site and installed there.

- This is no longer necessary with the RM 95-800 W high-performance bed cleaning machine, which is a fundamental innovation. By using pre-separator, impact mill, double sieve and washing plant, both heavily soiled and contaminated gravel is cleaned on site.

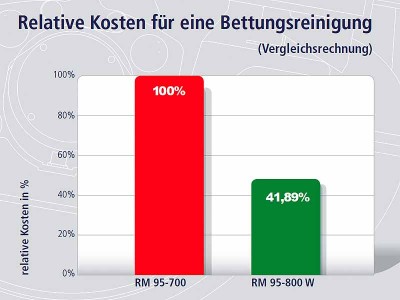

- This saves up to 58% of the costs.

Many truck journeys and thus harmful exhaust emissions are avoided.